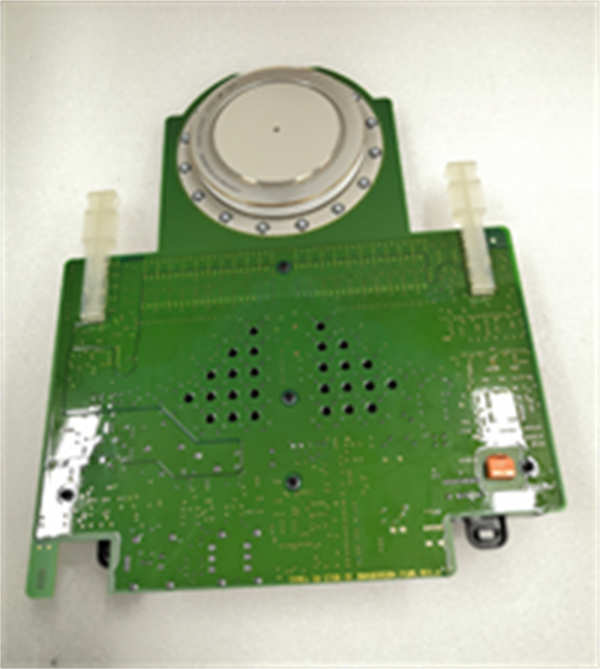

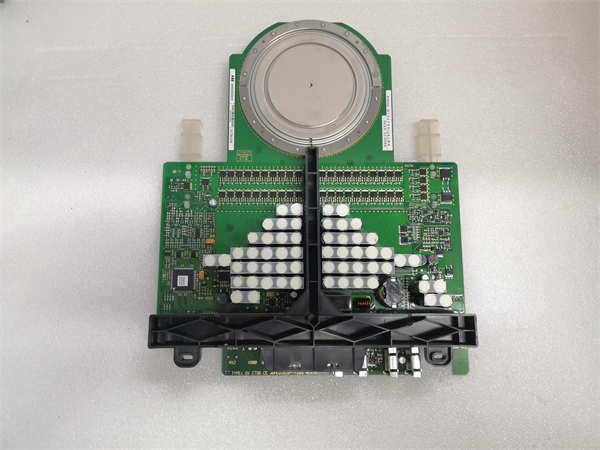

Description

Key Technical Specifications (For Spare Parts Verification)

| Parameter | Detail |

|---|---|

| Product Family | ABB ACS1000 / ACS6000 MV Drives (DTC Technology) |

| Function | IGCT gate pulse generation, isolation, and monitoring |

| Compatible Power Semiconductors | 5SHY4045L0006 IGCT (4.5 kV, 4 kA class) |

| Control Interface | Fiber-optic link from main control board (e.g., NIOC, AINT) |

| Power Supply Input | ±15 VDC and high-voltage bias rails from power cell |

| Diagnostic Features | IGCT status feedback, overcurrent detection, gate health monitoring |

| Mounting | Mounted directly on IGCT heat sink inside power cell enclosure |

| Cooling | Air-cooled (forced convection via drive cabinet fans) |

System Role and Downtime Impact

The GVC736CE101 (commonly labeled by its semiconductor part number 5SHY4045L0006) is a mission-critical sub-component within ABB’s IGCT-based medium-voltage drives, widely deployed in mining conveyors, oil & gas compressors, ship propulsion, and cement kilns. It resides inside the power cell and directly controls the turn-on/turn-off of the high-power IGCT—a key semiconductor enabling ABB’s Direct Torque Control (DTC).

This module receives low-energy optical commands from the central controller and converts them into precisely timed, high-current gate pulses (several amps) required to switch multi-kilovolt IGCTs. It also monitors IGCT health and reports faults via fiber back to the drive CPU.

If this gate driver fails:

- The associated IGCT does not switch correctly, causing DC bus overvoltage or phase imbalance

- The drive triggers a “Power Cell Fault” or “IGCT Fault” and trips immediately

- In multi-cell cascaded topologies (e.g., ACS1000), one failed cell may be bypassed—but repeated failures lead to derating or full shutdown

- Unplanned downtime can cost 500,000– 2M+ per day in heavy industry

Replacement requires:

- Full drive lockout and capacitor discharge (safety-critical HV procedure)

- Removal of the entire power cell from the stack

- Disassembly under ESD-controlled conditions

- Re-calibration or re-synchronization after reinstallation

Reliability Analysis and Common Failure Modes

Despite robust design, the gate driver is exposed to extreme electrical and thermal stress:

- Optocoupler/fiber interface degradation: Repeated high-dV/dt transients degrade the optical receiver, causing delayed or missed gate pulses → IGCT misfiring.

- Gate resistor burnout: High peak currents during switching fatigue the surface-mount gate resistors, leading to open circuits and loss of drive capability.

- PCB delamination or carbon tracking: Moisture ingress or dust accumulation in harsh environments creates conductive paths on the high-voltage PCB sections.

- Capacitor aging: Local decoupling capacitors dry out, reducing pulse fidelity and increasing EMI susceptibility.

A key vulnerability is thermal cycling fatigue: drives in cyclic duty (e.g., hoists, mills) cause repeated expansion/contraction, cracking solder joints or traces over time.

Preventive best practices:

- Perform annual infrared thermography on power cells during operation

- Monitor drive event logs for “IGCT desaturation” or “gate timeout” warnings

- Maintain clean, dry, and filtered cooling air (< ISO 8573-1 Class 2)

- Keep spare gate drivers in climate-controlled, anti-static storage

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

Lifecycle Status and Migration Strategy

ABB discontinued the ACS1000/ACS6000 platforms in favor of the ACS6080 (liquid-cooled) and Ability™-enabled drives, which use modern IGBT or IGCT modules with integrated gate drivers and advanced diagnostics. The 5SHY4045L0006 / GVC736CE101 has been obsolete for over a decade.

No new production exists. Secondary-market units are often:

- Recovered from scrapped drives

- Missing firmware or calibration data

- Suffering from latent damage due to prior overloads

Short-term mitigation:

- Source and functionally test spares using ABB’s DriveComposer or third-party IGCT testers

- Implement cell redundancy strategies where possible (e.g., N+1 configuration)

- Stock complete power cells (not just gate boards) to reduce repair time

Long-term strategy:

- Plan phased migration to ABB Ability™ ACS6080 or ACS880 MV platforms

- Leverage ABB’s Life Cycle Service Agreements (LCSA) for extended support

- Consider retrofit solutions from specialized firms that offer modern gate driver drop-in replacements with improved reliability

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: