Description

Key Technical Specifications (For Spare Parts Verification)

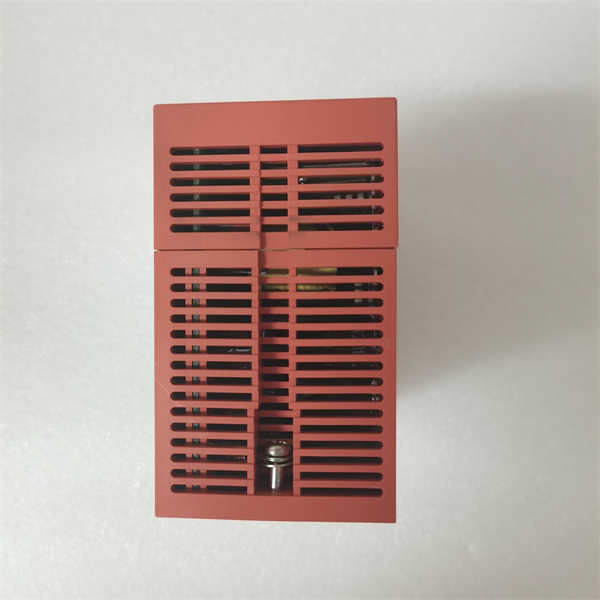

- Product Model: A1S61PN

- Manufacturer: Mitsubishi Electric

- System Family: MELSEC A1S Series PLC

- Input Voltage: 100–240 VAC, 50/60 Hz (auto-ranging)

- Output Voltages: +5 VDC (for backplane logic), +24 VDC (for I/O and external loads)

- Rated Output Current: Typically 6 A on +5V rail, 0.7 A on +24V rail

- Mounting Position: Leftmost slot in A1S base unit (mandatory location)

- Fuse Protection: Internal primary-side fuse (non-replaceable without board-level repair)

- Status Indicators: Power ON LED (green)

- Dimensions: Standard A1S single-slot width (approx. 27.4 mm)

- Cooling Method: Convection-cooled (no fan)

System Role and Impact of Failure

The A1S61PN is the foundational power source for an entire A1S PLC rack. It converts mains AC into the stable DC voltages required by the CPU (e.g., A1SCPU), digital/analog I/O modules, and communication cards. Without functional power from this module, the entire control system becomes inoperable—no logic execution, no field signal processing, and no communication with HMIs or SCADA. In continuous-process industries (e.g., water treatment, legacy manufacturing lines), failure of the A1S61PN results in immediate and total plant or line stoppage. Because the A1S architecture lacks redundant power options, this single point of failure represents a high operational risk in aging installations.

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the A1S61PN is now decades old in many installations, and component aging is inevitable.

Common failure modes include:

- Drying out or bulging of electrolytic capacitors on the primary and secondary sides, leading to voltage droop, ripple, or complete output loss.

- Degradation of the switching transformer insulation, causing intermittent shutdowns or overvoltage events that can damage downstream modules.

- Failure of the internal varistor or rectifier bridge due to repeated power surges or lightning-induced transients.

- Corrosion on terminal blocks or PCB traces in humid environments, increasing contact resistance and heat generation.

Design limitations include:

- No remote monitoring or diagnostic output (e.g., “power good” signal).

- Non-redundant architecture—no option for dual power supplies in A1S racks.

- Limited surge protection by modern standards, making it vulnerable to grid disturbances.

Preventive maintenance recommendations:

- Measure output voltages under load annually using a calibrated multimeter; acceptable tolerance is typically ±5%.

- Inspect for physical signs of stress: bulging capacitors, burnt smell, discoloration near power components.

- Ensure adequate ventilation around the PLC cabinet; ambient temperature should not exceed 55°C.

- Keep at least one tested spare A1S61PN powered up for 24 hours every 12–18 months to reform capacitors and verify stability.

MITSUBISHI A1S61PN

Lifecycle Status and Migration Strategy

Mitsubishi Electric ceased production of the A1S series long ago and offers no official repair or replacement program for the A1S61PN. Continuing to operate on this platform carries significant risks: escalating spare costs, inability to meet insurance or safety audit requirements, and growing difficulty in finding technicians familiar with A-Series programming (MEDOC or early GX Developer).

As a temporary measure, facilities may source used A1S61PN units from industrial surplus dealers, but rigorous testing under full load is essential before installation.

Mitsubishi’s recommended migration path is a full upgrade to the Q Series or iQ-R Series PLC platform. This involves:

- Replacing the entire A1S rack with a QnUDE or iQ-R base unit.

- Rewiring I/O to compatible QD/QX/QY or L/LX/LY modules.

- Converting ladder logic from MEDOC/A1S format to GX Works3 (for iQ-R) or GX Works2 (for Q Series)—a process that often requires re-engineering due to architectural differences.

- Updating HMI and SCADA drivers to support MC Protocol over Ethernet.

For applications where full migration is not immediately feasible, some integrators offer “PLC emulation” solutions using modern controllers that mimic A1S I/O mapping and communication behavior, allowing gradual retirement of legacy hardware while preserving existing field wiring. However, such approaches require thorough validation to ensure functional equivalence.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: