Description

Key Technical Specifications (For Spare Parts Verification)

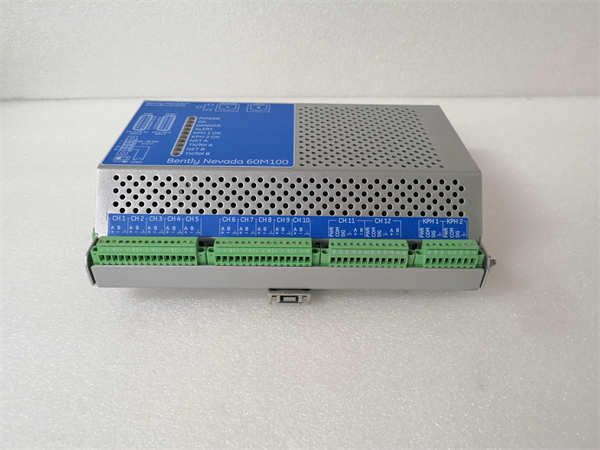

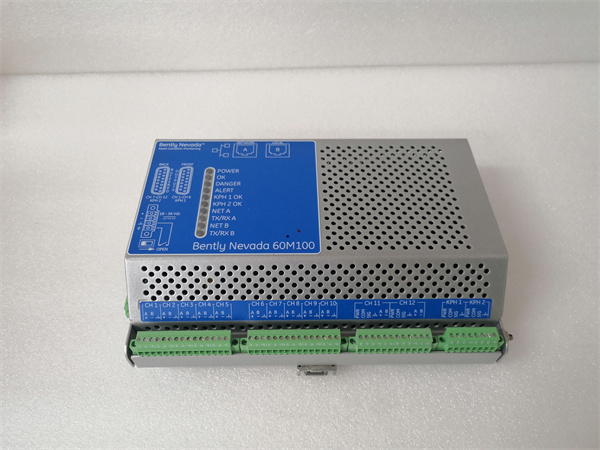

- Product Model: 60M100-00

- Manufacturer: Bently Nevada

- System Platform: Standalone monitor (pre-3500 era), often used with 7200 or 3300 series proximity probe systems

- Input Signal: -24 VDC powered eddy-current proximity probe (typically 8 mm), accepts displacement input in mils or microns

- Measurement Type: Peak-to-peak displacement (for slow-speed machines) or RMS velocity (with optional integrator module)

- Alarm/Trip Outputs: Two independent SPDT relay contacts (Alarm and Danger/Trip)

- Setpoint Adjustment: Front-panel potentiometers with lockable covers

- Power Supply: 115/230 VAC, 50/60 Hz (internal power supply)

- Mounting: Panel mount (standard 19″ rack or custom enclosure)

- Operating Temperature: 0°C to +50°C

- Approvals: CE, CSA (depending on vintage)

System Role and Downtime Impact

The Bently Nevada 60M100-00 was widely deployed in the 1980s–1990s as a compact, single-channel vibration monitor for medium-critical machinery such as boiler feedwater pumps, cooling water pumps, and small steam turbines. It typically interfaces directly with a proximity probe and driver (e.g., 3300 XL system) and drives relay contacts that feed into a plant-wide emergency trip system or PLC. In this role, it serves as a final layer of mechanical protection—triggering alarms at elevated vibration and initiating automatic shutdowns at dangerous levels. If the unit fails due to component aging or calibration drift, it may either fail to trip during a developing fault (risking catastrophic bearing or seal failure) or nuisance-trip during normal operation (causing unplanned process interruption). Because it lacks digital communication or self-diagnostics, faults are often discovered only after a machine incident, making it a hidden risk in otherwise well-maintained facilities.

Reliability Analysis and Common Failure Modes

The 60M100-00 is susceptible to several age-related failure mechanisms common in analog-era industrial electronics. The most prevalent issue is drift in the front-panel potentiometers used for alarm/trip setpoints, caused by oxidation or mechanical wear—leading to incorrect trip levels. Electrolytic capacitors in the internal power supply and signal conditioning circuits degrade over time, resulting in noisy output, intermittent relay operation, or complete power loss. The relay contacts themselves can oxidize or weld shut after years of service, compromising safety function integrity. A key design limitation is the absence of loop-powered isolation; the unit shares ground references with the probe system, making it vulnerable to ground loops and electrical noise in modern plants with variable frequency drives (VFDs). For preventive maintenance, technicians should annually verify setpoint accuracy using a calibrated signal simulator, inspect for bulging capacitors, test relay continuity under load, and ensure clean, tight terminal connections. Keeping the unit in a temperature-controlled panel also slows component aging.

BENTLY 60M100-00

Lifecycle Status and Migration Strategy

Bently Nevada officially discontinued the 60M100 series decades ago, with no factory support or new units available. Remaining inventory consists of old surplus stock, often untested and stored under unknown conditions—posing significant reliability risks. Continued use contradicts modern functional safety standards (e.g., IEC 61508) due to lack of diagnostics and proof-test coverage. As an interim measure, some sites perform board-level repairs or source tested-used units, but this is not a sustainable strategy. The recommended migration path is replacement with a modern, certified solution. For minimal disruption, the Bently Nevada Guardian series (e.g., 146030-01) offers single-channel monitoring with Modbus output, self-diagnostics, and direct compatibility with existing 3300 probes. For integration into larger protection architectures, migration to the 3500 system with a 3500/42M or 3500/45 monitor provides enhanced capabilities, redundancy, and compliance with API 670. Both paths require re-engineering the I/O wiring and updating trip logic in the control system, but eliminate long-term obsolescence risk and improve overall machinery reliability visibility. A phased approach—starting with highest-risk machines—is strongly advised.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: