Description

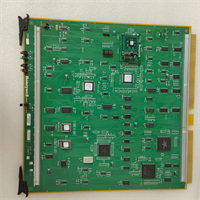

Technical Specifications (For Spare Part Verification)

- Product Model: TK-FTEB01

- Manufacturer: Honeywell

- System Family: Experion PKS (Process Knowledge System), primarily C300 and earlier controllers

- Function: FTE (Fail-Tolerant Ethernet) field termination block

- Mounting: DIN rail compatible, typically installed in control or marshalling cabinets

- Connector Type: Screw-clamp terminals for dual Ethernet (RJ-45 not used; direct cable termination)

- Cable Support: Dual Cat 5e/Cat 6 shielded twisted pair for redundant A/B FTE networks

- Shielding: Integrated grounding point for cable shields to maintain EMC integrity

- Compatibility: Designed for use with Honeywell FTE-enabled devices (e.g., C300, FTE switches)

- Mechanical Design: Passive terminal block—no electronics, firmware, or power required

System Role and Downtime Impact

The TK-FTEB01 is a passive but essential component in Honeywell Experion PKS architectures that rely on Fail-Tolerant Ethernet for high-availability control. It terminates the dual redundant Ethernet cables from field devices or remote I/O racks directly at the controller or switch cabinet, ensuring proper grounding and strain relief. While it contains no active circuitry, its role in maintaining signal integrity and network redundancy is critical. A faulty or poorly terminated TK-FTEB01 can cause intermittent network faults, packet loss, or complete link failure on one FTE leg. In non-redundant configurations—or if both legs are compromised—this may trigger controller switchover events or, in worst cases, loss of communication with safety-critical process units (e.g., reactor controls, boiler management). Such failures often lead to partial or full plant trips, especially in oil & gas, refining, or chemical facilities where Experion PKS is widely deployed.

Reliability Analysis and Common Failure Modes

As a purely mechanical/electrical interface, the TK-FTEB01 does not “fail” electronically, but its reliability is highly dependent on installation quality and environmental conditions. Common issues include loose screw terminals due to vibration or thermal expansion, leading to increased contact resistance and signal degradation. Corrosion of copper terminals in humid or corrosive atmospheres (e.g., offshore platforms) can also impair conductivity. Improper shield grounding—either missing or daisy-chained—compromises electromagnetic compatibility, making the FTE network susceptible to noise from VFDs or radio transmitters. Additionally, excessive bending or tension on terminated cables can damage internal conductors over time. For preventive maintenance, technicians should inspect terminal tightness during outages, verify single-point shield grounding to the cabinet earth bar, check for discoloration or oxidation on contacts, and ensure cable strain relief is properly secured to avoid stress on terminations.

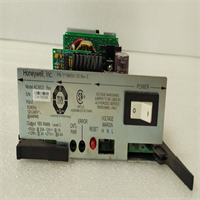

TK-FTEB01 HONEYWELL

Lifecycle Status and Migration Strategy

Honeywell has discontinued the TK-FTEB01 as part of its transition toward newer networking standards and modular I/O solutions in the Experion ecosystem. Official support is limited, and new units are no longer available through standard channels. Continued use carries operational risk: replacement units are scarce, and improper substitutes (e.g., generic terminal blocks) may violate FTE network specifications, voiding system certifications. As a short-term measure, facilities can maintain a strategic spares inventory, perform periodic torque checks on terminals, and document exact wiring configurations for rapid replacement. For long-term sustainability, Honeywell recommends migrating to modern Experion releases (e.g., Experion LX or PKS V5+) that utilize standard industrial Ethernet with managed switches and enhanced cybersecurity. While the FTE concept remains supported in newer systems, physical interfaces have evolved—often integrating termination within I/O modules or using pre-terminated trunk cables. Full migration may require updating network infrastructure, revalidating control logic, and retraining personnel, but it significantly reduces obsolescence exposure and improves interoperability with IIoT and cloud-based monitoring platforms. Early engagement with Honeywell or certified system integrators is advised to develop a phased migration roadmap.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: