Description

Key Technical Specifications (For Spare Part Verification)

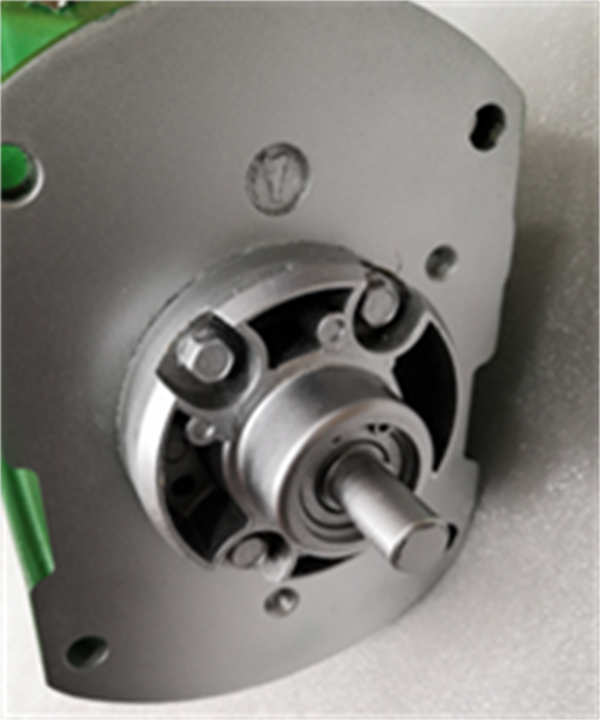

- Product Model: TG-13

- WOODWARD Part Number: 8516-038

- Manufacturer: WOODWARD

- System Family: Legacy TG series turbine control systems (pre-digital era)

- Input Signal: Typically ±10 V DC or 4–20 mA (depending on configuration)

- Output Type: Pilot hydraulic pressure signal to main servomotor or relay valve

- Operating Pressure Range: Commonly 30–150 psi hydraulic supply (varies by installation)

- Power Requirement: ±15 V DC or 24 V DC (for internal electronics, if present)

- Mounting: Panel or skid-mounted with hydraulic and electrical connections

- Feedback Mechanism: Mechanical linkage or LVDT (in later variants)

- Environmental Rating: Industrial, often installed in turbine control cabinets near lube oil/hydraulic systems

System Role and Downtime Impact

The WOODWARD TG-13 functions as a critical electro-hydraulic transducer in older steam and gas turbine control systems. It bridges the gap between an analog electronic controller (such as a 505 or early-generation EGCP) and the high-force hydraulic actuators that move turbine inlet valves. In many mid-20th-century power plants, marine propulsion systems, or industrial drive applications, the TG-13 is the final control element responsible for translating speed or load commands into physical valve movement. Failure of this unit typically results in loss of turbine speed regulation—triggering overspeed trips or forcing manual shutdown. Because it often operates without redundancy, a malfunction can cause immediate and complete turbine trip, leading to unplanned outages that may last days or weeks due to the difficulty in sourcing replacements. Its failure directly jeopardizes plant availability and operational safety.

Reliability Analysis and Common Failure Modes

The TG-13 combines precision mechanical components with early solid-state or analog electronics, making it susceptible to multiple aging-related failure modes. The most prevalent issue is contamination of the internal hydraulic spool valve by particulates in the oil system, causing sticking or sluggish response—a frequent root cause of hunting or instability. Internal torque motor coils can degrade due to thermal cycling, leading to open circuits or reduced magnetic force. In units with electronic feedback boards, electrolytic capacitors often dry out over time, distorting the control signal. Additionally, O-ring and seal hardening from prolonged exposure to hot hydraulic fluid results in internal leakage, reducing actuator authority.

Environmental factors such as vibration, moisture ingress, and oil mist accelerate wear. Preventive maintenance should include regular inspection of hydraulic fluid cleanliness (ISO 4406), verification of input signal integrity, functional stroke testing under no-load conditions, and visual checks for oil weepage around shaft seals. Where possible, installing inline hydraulic filters upstream of the TG-13 can significantly extend service life.

TG-13(8516-038)WOODWARD

Lifecycle Status and Migration Strategy

WOODWARD discontinued the TG-13 decades ago, with formal obsolescence notices issued well before 2000. No new units are manufactured, and technical support—including calibration documentation or repair manuals—is extremely limited. The few remaining units in circulation come from decommissioned equipment or broker inventories, often at high cost and uncertain condition. Continued reliance on this component poses severe operational and safety risks.

As an interim measure, some operators pursue third-party refurbishment or reverse-engineered replicas, though performance and certification may be unverified. A more robust solution is full migration to a modern digital governor system such as WOODWARD’s MicroNet™ Plus or SLC (Simplified Load Controller) platform. These systems replace the entire analog chain—including the TG-13—with integrated electro-hydraulic servo valves (e.g., MPT or EHA series) and programmable logic, offering improved accuracy, diagnostics, and compliance with current grid codes. While retrofitting requires hydraulic line modifications, updated I/O integration, and re-commissioning, it eliminates single-point obsolescence and provides long-term supportability. For facilities unable to fund a full upgrade, maintaining a verified spare TG-13 in climate-controlled storage remains a necessary—but increasingly precarious—contingency.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: